Our Partner Hydro

Discover our exciting partnership with Hydro, a global leader in sustainable aluminum production. In this blog, we delve into the eco-friendly practices that make Hydro the perfect partner for us at UAB Tukas EV. Explore how choosing Hydro's sustainable aluminum products can help you make responsible choices for the environment without compromising on quality. Join us on a journey toward a greener future!

Guided by Shared Values

At Tukas EV, our commitment to a greener planet has always driven our choices, and this collaboration with Hydro is a testament to this pledge. Our partnership with Hydro, a luminary in sustainable aluminum production, promises a harmonious blend of innovation and environmental responsibility.

Delving into Hydro's Legacy

From their inception in 1906, Hydro has been at the forefront of the sustainable energy movement. Their initial venture into the renewable sphere started with a hydroelectric power plant at Svelgfoss, near Notodden in Norway. The link between hydropower and aluminum production began to solidify in 1963 when Hydro opened its first aluminum production plant on Karmøy, an island off the Norwegian west coast. Today, with a network of over 20 hydropower facilities throughout Norway, Hydro delivers around 10 TWh of clean and renewable energy each year for their aluminum production. This energy focus not only reduces their carbon footprint but emphasizes their dedication to green initiatives.

Aluminum: At the Core of Tukas EV

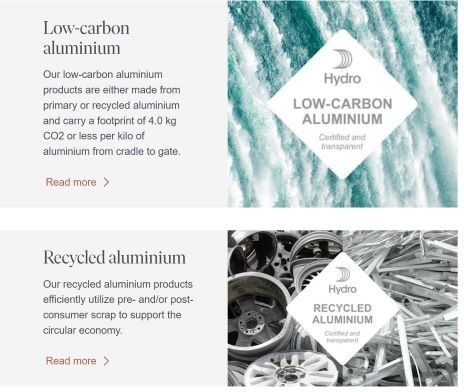

At Tukas EV, aluminum isn't just a component; it's integral to our vehicles. This metal needs to be both strong and lightweight, making it crucial to the performance and efficiency of our HR BANK. Hydro’s commitment to using renewable energy sources, particularly hydropower, to produce this aluminum means every Tukas EV vehicle not only promises top-tier performance but does so with an environmentally-friendly backbone.

Karmøy: Unveiling Aluminum Production's Future

The Karmøy pilot plant in Norway showcases Hydro's zeal for innovation. Here, they’ve introduced an aluminum production method that stands out as the world's most energy-efficient. Using novel technology, Hydro has managed to decrease energy consumption significantly. For instance, compared to the global average energy consumption of 14.1 kWh in aluminum production, Hydro’s Karmøy technology expends only 12.3 kWh. This advancement ensures that the aluminum incorporated into Tukas EV HR BANK is produced using methods that push boundaries and reduce ecological impact.

Harnessing the Power of Hydropower

It’s crucial to highlight the importance of using renewable energy in aluminum production. An aluminum plant powered by coal can emit up to five times more CO2 than one powered by renewable sources, such as hydropower. With Hydro's emphasis on hydropower, wind power, and solar power, we're confident that the aluminum in our vehicles is sourced responsibly, minimizing our collective carbon footprint.

Moving Ahead, Together

Our collaboration with Hydro is a step toward a future where environmental consciousness and superior performance go hand in hand. By uniting Tukas EV's vision with Hydro’s the concept of sustainability, we’re gearing to present a sustainable, high-quality, long-lasting product to humanity.

In Same Category

- HR Bank Wins Prestigious iF GOLD AWARD 2025 – Lithuania Enters Global Design History!

- HR Bank: More Than Just a Fitness Machine ⚡

- Nicolás Levy Fachena and HR Bank at EUROBIKE SHOW 2024

- New-gen power banks – for home or on the hoof

- Pedal power: This climate change play in Lithuania is activated using exercise bikes